钢丝编织胶管的安全系数检测时如何进行的?

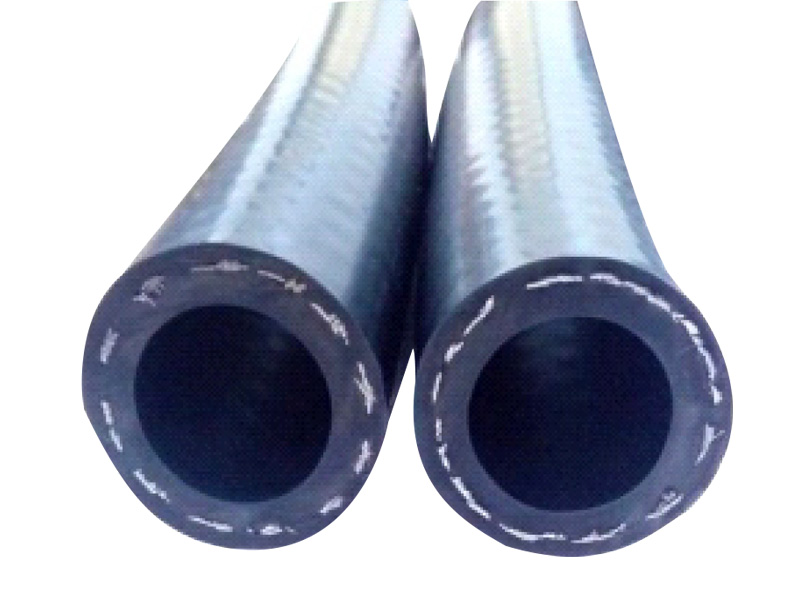

时间:2022-03-23浏览次数:2635钢丝编织胶管结构由耐液体合成橡胶内胶层、中间胶层、I或II或III钢丝编织增强层和耐候性优异的合成橡胶外胶层组成。特点:

1.胶管由特种合成橡胶制成,具有优异的耐油性、耐热性和耐老化性。

2.该胶管承受压力高,脉冲性能好。

3.管体结合紧密,使用柔软,受压变形小。

4.该软管具有优异的抗弯曲性和抗疲劳性。

5.钢丝编织胶管长度大,φ32以上20米,φ25以下10米甚至100多米。

那么,如何测试钢丝编织胶管的安全系数呢?

一、抗压强度测试

进行交流耐压试验,检查胶管的耐压能力是否达标,管体有无泄漏,零件有无损坏等异常现象,以确定胶管的安全系数是否优良。

二、密封性试验

高压胶管的密封性能测试是根据应用干洗气体或N2或其他气体作为检测物质,检测胶管内是否有气体泄漏。

三、胶管材质对称吗?

检查高压胶管质量是否对称,是否有胶液附着等不规则情况。如果存在这类情况,则是不合格的胶管。

四、韧性测试

将钢丝编织胶管适当弯曲,看其是否有一定的延展性,防止其在整个使用过程中因弯曲而非正常破裂,危及客户的一切正常使用。