The relationship between the production process and product quality of woven silicone tubing

Time:2025-02-28Page views:1097As an important material widely used in multiple fields, woven silicone tubing has an inseparable relationship between its production process and product quality. Understanding and optimizing this relationship can not only improve the performance of silicone hoses, but also meet the strict requirements of different industries.

The production raw materials for woven silicone hoses mainly include silicone rubber, fillers, additives, and vulcanizing agents. As the main material, the purity, processing performance, and high temperature resistance of silicone rubber have a decisive impact on product quality. High quality silicone rubber can ensure the stable performance of silicone tubes under extreme conditions, fillers are used to increase hardness and strength, additives are used to improve processing performance and heat resistance, and vulcanizing agents can keep silicone tubes stable at high temperatures. The accurate weighing and mixing of these raw materials are the foundation for ensuring the quality of silicone tubes. During the mixing process, it is necessary to control the mixing time and temperature to ensure that the mixture melts and becomes a paste with good fluidity.

After the raw materials are prepared, enter the extrusion molding stage. Extrusion technology is the process of extruding silicone rubber material into circular rubber tubes through an extruder. The shape and size of silicone tubing are determined by mold design, so the selection and preparation of molds are crucial. The mold preparation process includes steps such as drawing design, mold opening, processing, mold testing, and mold repair, which require precise consideration of factors such as the size, shape, and wall thickness of the silicone tube. During the extrusion process, the silicone material is extruded into shape through the pressure and temperature of the extruder. This step requires strict control of the extrusion speed and pressure to ensure the accuracy of the size and shape of the silicone tube. The extruded silicone tube also needs to undergo vulcanization treatment to improve its elasticity and heat resistance. The vulcanization process requires controlling the vulcanization temperature and time to ensure that the hardness, strength, and heat resistance of the silicone tube meet the requirements.

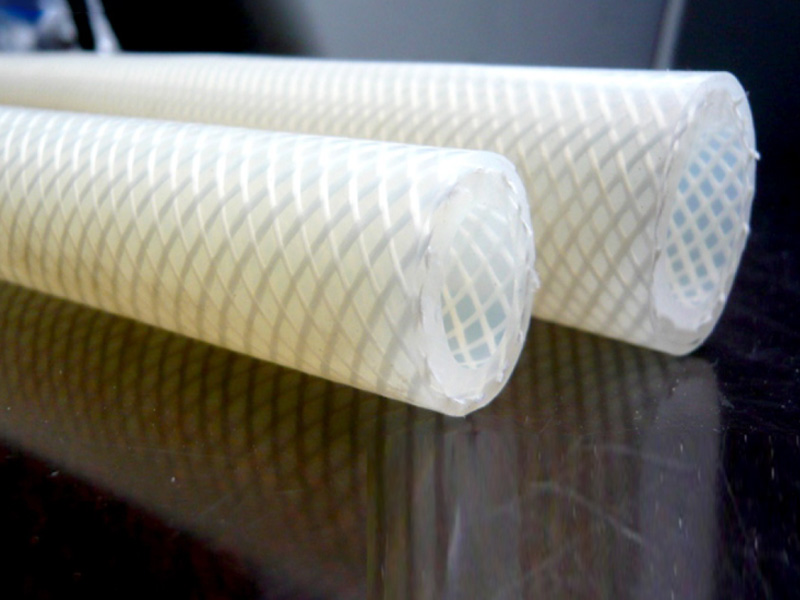

In the production process of woven silicone tubing, in addition to extrusion molding and vulcanization treatment, another important process is weaving. The weaving process can enhance the strength and pressure resistance of silicone tubing, making it more suitable for high pressure and complex environments. The selection of weaving materials and weaving density have a direct impact on the performance of silicone tubes. Suitable weaving materials and tight weaving density can significantly improve the strength and durability of silicone tubes. During the weaving process, it is necessary to ensure the uniform distribution and tight fit of the weaving material to avoid looseness or breakage.

Strict quality control is required at every stage of the production process to ensure stable and reliable product performance. After the production of silicone tubing is completed, a comprehensive quality inspection is required, including visual inspection, wall thickness measurement, quality testing, and performance testing. The appearance inspection mainly checks whether the surface of the silicone tube is smooth, free of bubbles, and has no crust phenomenon; Wall thickness measurement ensures that the wall thickness of the silicone tube meets the design requirements; Quality inspection verifies the strength and durability of silicone tubing through physical property tests such as tensile testing and aging testing; Performance testing includes pressure testing, temperature testing, etc., to ensure that the silicone tube can work properly under extreme conditions.

The quality of woven silicone tubing depends not only on the production process, but also closely related to the selection of raw materials. As the main material, the quality of silicone rubber directly affects the performance of silicone tubing. High quality silicone rubber has excellent high temperature resistance, oxidation resistance, and corrosion resistance, and can maintain stable performance under extreme conditions. The selection of fillers, additives, and vulcanizing agents also needs to be based on the specific requirements of the product. For example, for silicone tubes that require high hardness and strength, an appropriate amount of filler can be added; For silicone tubes that require high heat resistance, it is necessary to choose high-temperature resistant additives and vulcanizing agents.

The extrusion molding and vulcanization treatment in the production process have a significant impact on the performance of silicone tubes. During the extrusion molding process, it is necessary to strictly control the extrusion speed and pressure to ensure the accuracy of the size and shape of the silicone tube. Excessive extrusion speed or high pressure may cause defects or inaccurate dimensions on the surface of the silicone tube. During the vulcanization process, it is necessary to control the vulcanization temperature and time to ensure that the hardness and strength of the silicone tube meet the requirements. Excessive vulcanization temperature or time may cause problems such as cracking or deformation of silicone tubes.

The weaving process is equally important for the performance of silicone tubes, and the selection of weaving materials and weaving density need to be based on the specific requirements of the product. The woven material should have high strength and wear resistance to ensure that the silicone tube can work properly under high pressure and complex environments. The weaving density needs to be adjusted according to the purpose and working environment of the silicone tube to achieve the required strength and durability.

Strict quality control is required at every stage of the production process to ensure stable and reliable product performance. Quality inspection is an important means of ensuring product quality. Through comprehensive inspections such as visual inspection, wall thickness measurement, quality testing, and performance testing, problems in the production process can be discovered and solved in a timely manner, ensuring that the performance of silicone hoses meets design requirements. At the same time, a strict quality control system needs to be established during the production process, with real-time monitoring and recording of every step, so that when problems arise, the cause can be quickly traced and corresponding measures can be taken.

There is an inseparable relationship between the production process and product quality of woven silicone tubes. By optimizing the production process and strictly controlling the quality, the performance of silicone tubes can be significantly improved to meet the strict requirements of different industries. In the actual production process, it is necessary to adjust and optimize the processes of raw material selection, extrusion molding, vulcanization treatment, and weaving according to the specific requirements of the product. At the same time, establish a strict quality control system and quality inspection standards to ensure stable and reliable product performance. Only in this way can high-quality woven silicone tubes be produced, providing strong support for applications in various fields.