高压钢丝编织胶管疲劳寿命测试

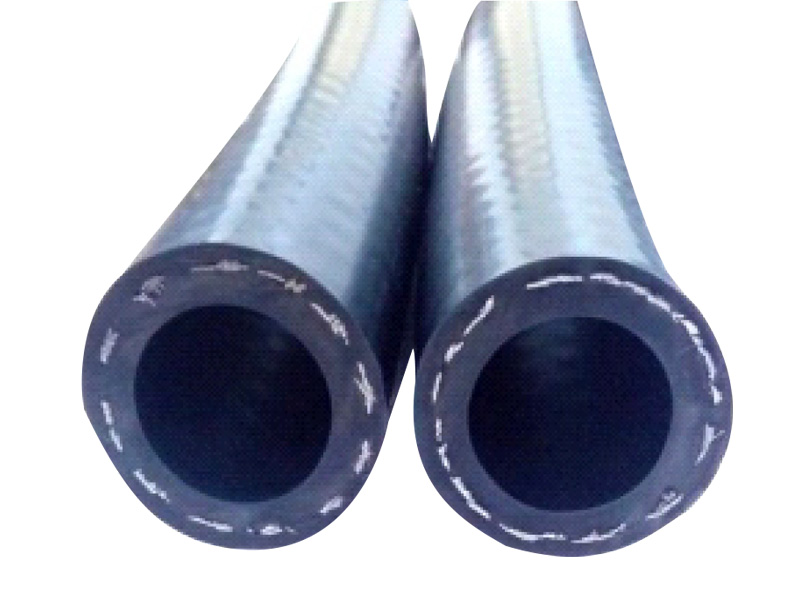

时间:2022-05-17浏览次数:2918在科学技术向生产力模式转变的今天,世界工业生产格局仍在发生巨大变化。高压钢丝编织胶管作为机械领域的常见产品,广泛应用于装载机、挖掘机、压路机、叉车、液压起重机等设备中。近年来,由于石油、采矿、农业和工业的需求日益增加,对能适应环境和满足工业生产需要的高压钢丝编织胶管产品的需求很大。

高压钢丝编织胶管主要用于煤炭、石油等行业输送具有一定温度和压力的液体,为了了解高压钢丝编织胶管的产品性能,生产厂家和质检单位需要设置一定的压力和温度控制环境,使被试件达到实际工作状态进行疲劳寿命试验,确定产品性能。测试方法如下:

1、PTM系列软管脉冲试验机

PTM系列软管脉冲试验机采用自动伺服控制系统,可自行设定脉冲压力、脉冲频率、试验次数和脉冲波形,具有设备标本损坏后自动关机保护功能。主要部件为进口件,安全可靠;界面动态显示测试数据,绘制实时压力波形,生成测试报告并打印。

2、BTM系列软管爆裂测试仪

本发明能够满足0.01~350Mpa橡胶软管爆破压力的高低压要求,可以对高压管汇、高压裸管、管接头进行耐压、耐压和爆破试验。增压控制方式有十余种,可满足不同管径、压力、增压率和曲线的要求。

除了安全可靠的产品质量外,根据使用要求选择合适的软管产品也是确保整个系统安全性和合理性的重要因素。选择高压钢丝编织胶管时,应注意以下几点:

1、根据系统压力选择胶管钢丝层数,压力越高,钢丝层数越多。每根软管的工作压力都很高,软管的爆破压力是大工作压力的4倍。因此,根据实际系统压力,所选软管的大工作压力可以略高于实际工作压力。

2、根据流速选择软管的内径,如果管径过小,会增加管内介质的流量,使系统升温,降低效率,产生过大的压降,影响整个系统的性能。管径太大会增加成本,所以软管内径要合适。用管夹固定软管或软管穿过垫片(如钢板)时,要注意软管的外径。

选择高压钢丝编织胶管要注意弯曲半径,计算弯曲半径时减去前接头的压接长度。如果安装的软管弯曲半径过小,软管的承压能力会降低,使用寿命也会受到影响。