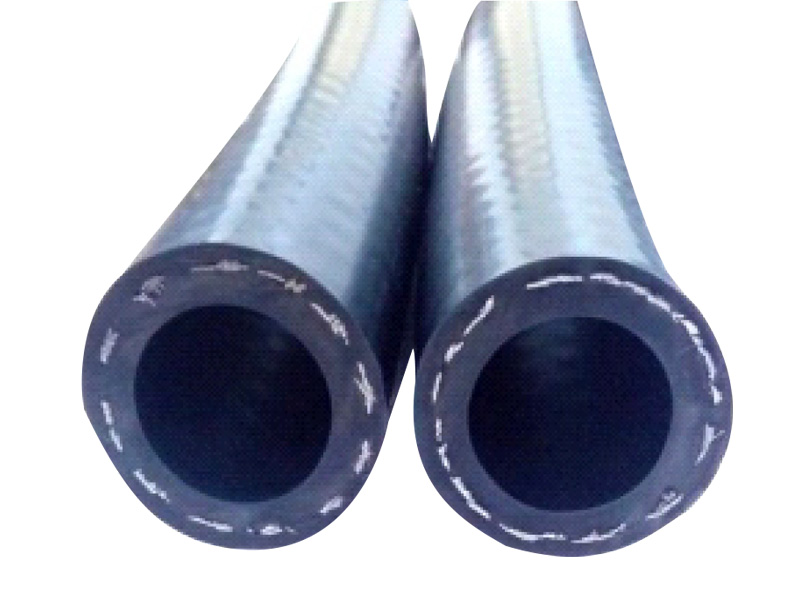

Common materials for high-pressure steel wire braided rubber hoses

Time:2022-09-28Page views:3795The materials used for high-pressure steel wire braided rubber hoses are divided into non-metallic materials and metallic materials. Non metallic materials commonly used in the production process include nitrile rubber, styrene butadiene rubber, chloroprene rubber, etc., while metallic materials include copper plated steel wire and galvanized steel wire with circular cross-sections.

With the advancement of technology and the development of the rubber industry, EPDM rubber, chlorosulfonated polyethylene, epichlorohydrin rubber, hydrogenated nitrile rubber, etc. are gradually being applied in high-pressure hose products. Non metallic reinforcement materials include nylon and polyimide fibers. With the advancement of computer simulation and testing, flat steel wire (copper plated steel wire with elliptical cross-section) will be used for high-pressure hoses.

(1) EPDM rubber: It has excellent heat resistance, steam resistance, weather resistance, chemical corrosion resistance, and excellent electrical insulation, especially its resistance to ethylene glycol ether brake fluid and vegetable oil. It is suitable for manufacturing rubber hoses with strong high temperature resistance, steam resistance, and corrosion resistance.

(2) Chlorosulfonated polyethylene rubber: It has excellent ozone resistance, weather resistance, chemical corrosion resistance, flame retardancy, oil resistance, and tear resistance, and is suitable for manufacturing rubber hoses with strong corrosion resistance, flame retardancy, and ozone aging resistance. It is particularly suitable for manufacturing the outer layer of high-pressure steel wire braided rubber hoses used in harsh environments.

(3) Chlorinated ether rubber: It has excellent weather aging resistance, oil resistance, and solvent resistance. Good flame retardancy and low breathability, suitable for manufacturing rubber hoses that are resistant to oil, ozone, weather, and low breathability.

(4) Hydrogenated nitrile rubber: It has excellent oil resistance, corrosion resistance, high and low temperature resistance, oxidation resistance, dynamic fatigue resistance, and ozone resistance. Suitable for manufacturing rubber hoses with special requirements such as oil resistance.

(5) Acrylonitrile rubber/PVC: It has excellent oil resistance, wear resistance, and ozone resistance. Good extrusion performance, easy to process, suitable for manufacturing outer layer adhesive for rubber hoses used in wear-resistant and ozone resistant environments.

(6) Aramid fiber: Aramid fiber has high strength, high modulus, high temperature resistance, acid and alkali resistance, and light weight. Its strength is 7 times that of steel wire. The modulus is 2-3 times that of steel wire or fiberglass. Its toughness is twice that of steel wire, and its quality is only about 1/5 of that of steel wire. It will not decompose or melt at a temperature of 450 ℃, and has good insulation and aging resistance.

(7) Flat steel wire: It has high strength, high modulus, high temperature resistance, and good pressure bearing performance, especially good resistance to torsion and bending deformation. The pulse performance of high-pressure steel wire braided rubber hoses made of flat steel wire is much better than that of hoses made of high-strength (ultra high strength) steel wire.