Overview of Safety Factors in the Use of High Pressure Steel Wire Braided Rubber Hose

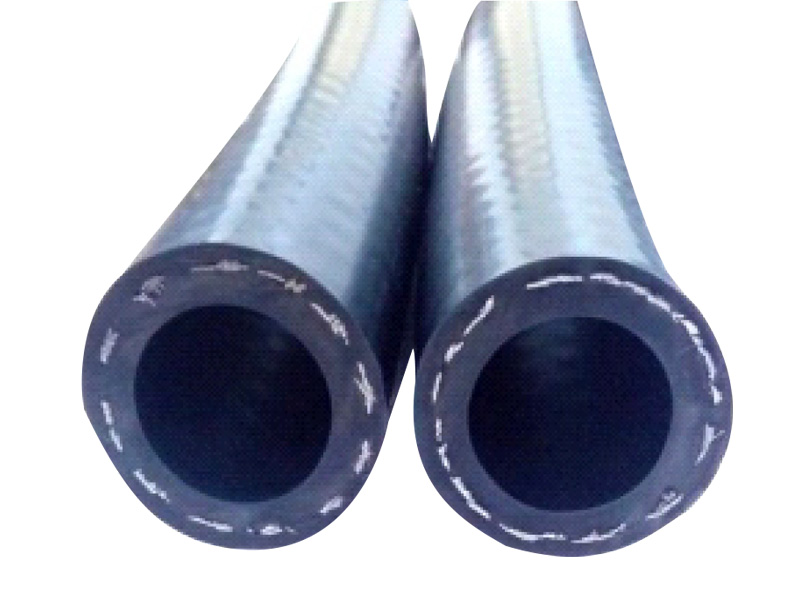

Time:2022-10-08Page views:3488The application scenarios of high-pressure steel wire braided rubber hoses that we are familiar with are usually industries such as oil extraction, mining, metallurgy, forging, etc. Therefore, the material of steel wire braided high-pressure rubber hoses should be strictly controlled. In such an environment, if the safety value of the material is not paid attention to and the operation is improper, it is easy to cause accidents. The following will provide an overview of the safety elements involved in the use of high-pressure rubber hoses.

Installation precautions:

1. Do not twist the rubber hose during installation, otherwise it may damage the hose or cause the joint to loosen.

2. When the bending radius of the hose is too small, a right angle joint is usually used to avoid sharp bending and deformation of the high-pressure hose.

3. In order to avoid damage to the hose and flow limitation, the bending radius of the pipe body should be increased as much as possible.

4. During normal operation, the valve stem should not be pulled too hard.

5. When the temperature rise of the hydraulic system is too high during operation, the high-pressure oil pipe should be checked in a timely manner, and corresponding cooling measures should be taken during continuous operation.

6. When installing high-pressure hoses between objects, a certain amount of space should be left to avoid friction between the high-pressure hoses and the objects during operation. If it cannot be avoided, then find a way to take some maintenance measures. For example, a high-pressure hose sheath.

Precautions for use:

1. The working pressure of high-pressure steel wire braided rubber hoses should be greater than the peak pressure of the system, and high-pressure rubber hoses used in normal oil drilling can only be used in a few cases. It only allows for a 20% increase and a 40% reduction in frequent bending and twisting. The impact pressure of the system is higher than the specified working pressure of the metal hose, which not only reduces its service life, but also causes equipment failure due to hydraulic hose.

2. Temperature, fluid temperature, and ambient temperature are all stable and transient. It is recommended that the heat-resistant temperature should not exceed the limit temperature, which is higher or lower than the heat-resistant temperature of rubber hoses. This may reduce the performance of rubber hoses, leading to damage and leakage.

3. Fluid compatibility, the fluid of the hose should comply with the "use" regulations of the product sample, and the product characteristics of the high-pressure steel wire braided hose should be managed and life safety should be in accordance with the requirements during use.

4. A suitable connection end, due to the convenience and low cost of nut connection, wide application, and large vibration under allowable conditions, should fully consider the tightness of the nut, and flange connection is recommended.

In use, the correct use of high-pressure steel wire braided rubber hoses can be determined based on the above safety factors. Proper use can effectively avoid malfunctions during use.