咖啡机所用编织硅胶管抗压需求

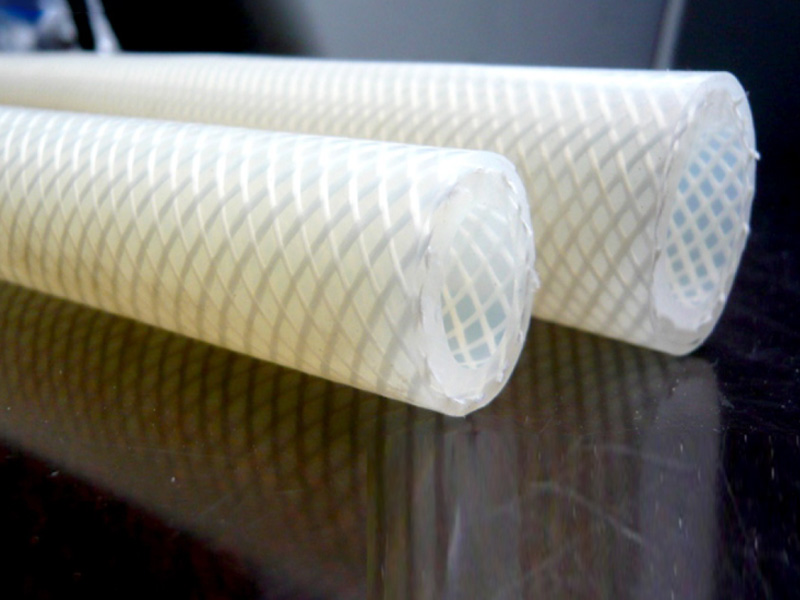

时间:2023-01-12浏览次数:2250咖啡机可以节省冲泡咖啡的时间,设备的冲泡过程是在高温高压下进行的,而硅胶作为一种耐高温材料,需要达到食品级的要求和抗压要求才能安装使用。目前咖啡机一般的压缩要求是30~40KG。咖啡机使用的是编织硅胶管,这是因为普通的硅胶管抗爆压力偏低,没有进行编织工艺的硅胶管达不到抗压需求。

编织后的硅胶管能将咖啡机内部的压力阻力传递给机织物,机织物以网状结构编织,将压力细分给其他机织物。为了防止在较高的压力冲击下断裂,通常在织物外面加一层硅胶管。压力可以通过硅胶、机织物、外层硅胶三个环节循环,使每个面平均承受压力,但也有上限,爆破压力不能超过45kg。

编织硅胶管既要达到FDA食品级又要能承受咖啡机工作时的高压环境,故而厂家挤出时会选用高透明、品质的硅胶材料,从源头上解决问题。另外,在原有基础上进行二次硫化能稍微提高爆破压力上限,通常二次硫化后,原30~35 kg左右的爆破压力提高到≥38 kg。织好后,对硅胶进行再次硫化,整个硅胶编织管会收缩紧密贴合,这样各个压缩点会更加均匀,不容易断裂。

编织硅胶管的承压能力能比其它硅胶管强是因为编织工艺,导致每平方米能承受的爆炸压力比其它硅胶管高,且硅胶管的口径会影响到抗压力,胶管的尺寸越小,壁厚越厚,所能承压压力越高。