What are the requirements for selecting and installing high-pressure steel wire braided rubber hoses

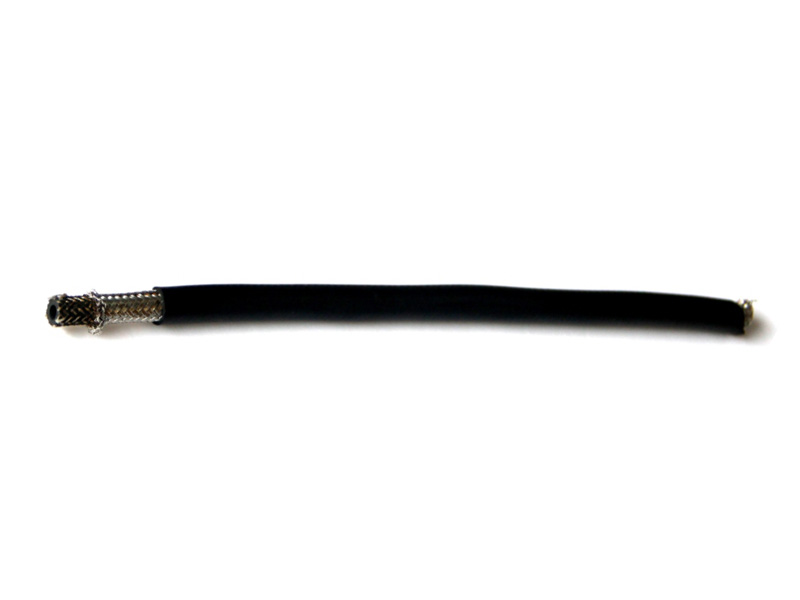

Time:2022-08-16Page views:3916High pressure steel wire braided rubber hose has the function of fire and fire prevention, and can be used in harsh environments such as steel mills with high working temperatures. So what are the requirements during processing? Next, let me briefly introduce the relevant knowledge points of high-pressure braided rubber hoses. When processing, it is necessary to pay attention to the working pressure of the environment, select the corresponding black high-pressure hose, and determine the length of the hydraulic hose assembly. The length should be moderate, neither too short nor too long. After determining the length, armor should be applied. If the external environment is high, asbestos should be added to achieve flame retardancy. Usually, a layer of asbestos can be added; If the external temperature is too high, two layers of asbestos should be added; If the external temperature is too high, a silicone fireproof sheath should be added to the black high-pressure hose.

When installing high-pressure steel wire braided rubber hoses, try to avoid heat sources and stay away from the engine exhaust pipe. If necessary, a sleeve or protective net can be used to prevent the hose from deteriorating due to heat. When working with high-pressure hoses, protective devices such as hose clamps or springs should be used where they need to pass through or may rub against mechanical surfaces to prevent damage to the outer layer of the high-pressure hose. When it is necessary to bend high-pressure rubber hoses, the bending radius should not be too small and should be greater than 9 times the outer diameter. The connection between the hose and the joint should have a straight pipe section that is twice the outer diameter of the pipeline. When installing the hose, it should be avoided to be in a tight state. Even if there is no relative movement between the two ends of the hose, it should remain loose. A tensioned hose will expand under pressure, and its strength will decrease. Do not twist the rubber hose during installation, as twisting the hose may reduce its strength and loosen the joint. When assembling, the joint should be fastened onto the hose, not onto the hose.

The above are the knowledge points related to high-pressure steel wire braided rubber hoses. If you have any questions or want to consult, you can visit the official website for more information.