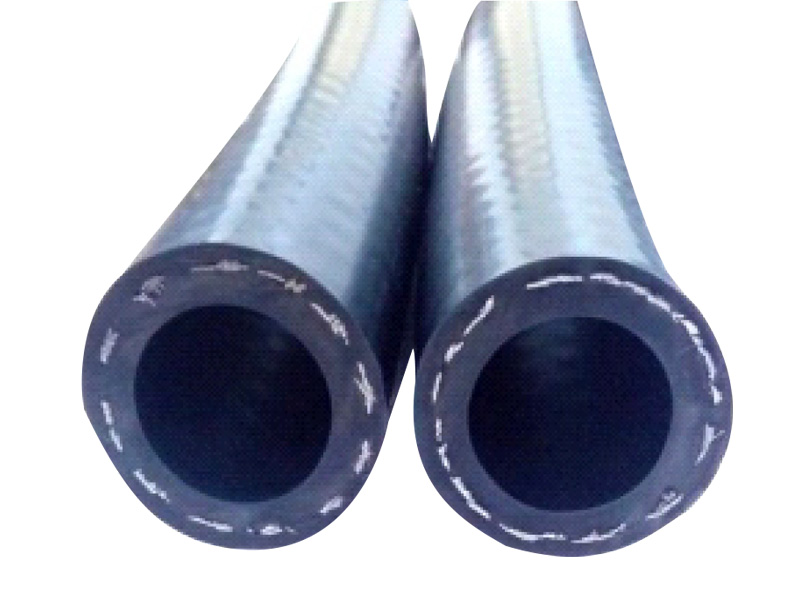

Storage and maintenance of woven rubber hoses

Time:2022-08-08Page views:2420The use, storage, and transportation of woven rubber hoses will inevitably cause certain damage to the hoses. These damages are difficult to detect, but they accumulate over time. If you don't pay attention to the use of rubber hoses, they will age faster. So how to transport and maintain rubber hoses to extend their service life?

1. Transportation

When transporting and loading/unloading goods, be careful and do not place heavy objects on top. Moreover, the hose should not be excessively twisted when placed, as transportation often takes a long time. If it is highly bent for a long time, it will cause significant damage to the hose itself. Secondly, during transportation, the rubber hose should not be mixed with substances such as acid, alkali, organic solvents, oil, etc., to avoid chemical reactions between these substances and the rubber hose. It cannot be placed together with goods with sharp parts to avoid scratching the rubber hose due to collision during transportation.

2. Storage

When storing, the inside of the braided rubber hose should be emptied first, especially corrosive acids, alkalis and other substances should not be left inside. No matter where the hose is stored, as long as it is not isolated from the outside world, it will continue to age, just at different speeds. The factors that affect the rate of oxidation reaction include temperature, ultraviolet radiation, oxygen concentration, etc. When storing, the rubber hose should be kept away from light, ventilated, and there should be no heat sources nearby. It should also not come into close contact with equipment that can produce ozone, as ozone has much greater oxidizing properties than oxygen.

3. Use

To determine the nature of the medium conveyed by the hose and whether the hose can transport this medium. For example, when transporting oil, EPDM rubber hoses cannot be used, and oil resistant nitrile rubber hoses should be used. And try to avoid dragging the inner braided rubber hose during work, as it may cause damage to the outer rubber layer of the hose. In addition, the work pressure should be within a certain range, otherwise it may damage the pipe material; At the same time, not working in water or fire for a long time can also accelerate the aging of the hose.