Introduction to the Forming Temperature of Steel Wire Braided Rubber Hose

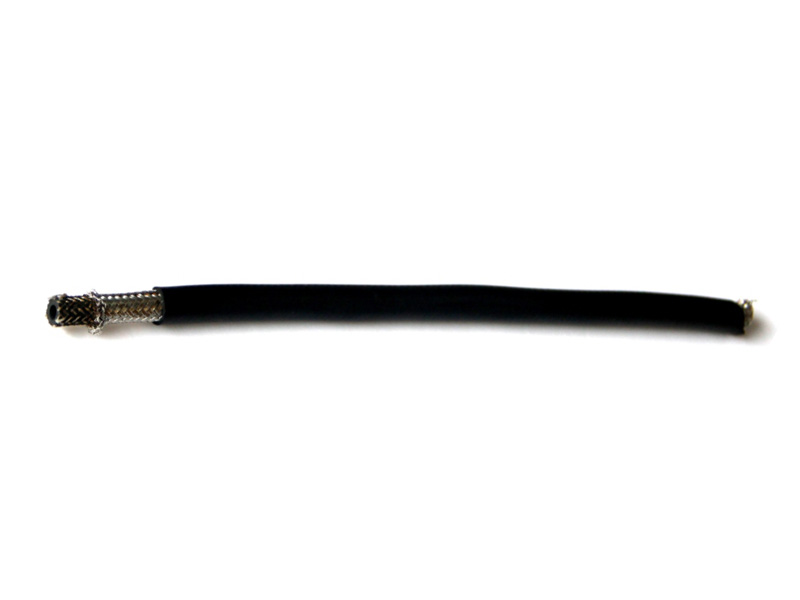

Time:2023-02-09Page views:2744From the moment the steel wire braided rubber hose was put into the market, it was destined to have a broad prospect and was widely used in hydraulic systems. But this is only a small scope of application, and with the development of its application products, its scope of application is constantly expanding.

One of the things to pay attention to when making steel wire braided rubber hoses is the molding temperature. Only by mastering the molding temperature can high-quality high-pressure rubber hoses be produced. Below is a brief introduction to the relevant molding temperature.

1. The rubber hose raw materials are mechanically mixed with plasticizers after calculation, and the specific requirements are the same as the mixing method of PVC hose raw materials. When the temperature of the material reaches 110-120 ° C, it is discharged into the cold mixer and mixed to break down the clumped material, so that the temperature of the evenly mixed material drops below 45 ° C.

2. For the inner layer formed by extrusion, the temperature of the feeding section of the extruder barrel is 90-120 ℃, the temperature of the plasticizing section is 130-150 ℃, the temperature of the homogenization section is 160-170 ℃, and the temperature of the forming mold is 170-180 ℃.

3. For the outer layer of extruded laminated steel wire fiber hoses, the temperature of the feeding section of the extruder barrel is 110-130 ℃, the temperature of the plasticizing section is 140-160 ℃, the temperature of the homogenization section is 160-170 ℃, and the temperature of the forming mold is 170-180 ℃.

The above is an introduction to the forming temperature of steel wire braided rubber hoses, and their working pressure is usually one fourth of the burst pressure value according to regulations. Quality is also affected by temperature. If the working temperature exceeds the appropriate range of use, it will affect the service life of the hose. Attention should be paid to the bending radius of the hose assembly. If the bending radius is too small, it will directly affect the load-bearing capacity of the high-pressure hose.