The difference in usage between woven silicone tubing and transparent silicone tubing

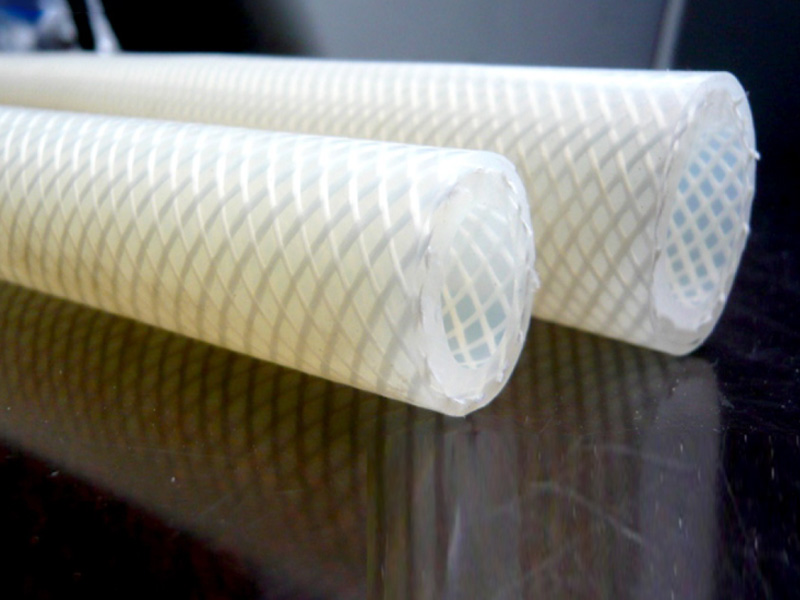

Time:2023-02-07Page views:2878There are many types of silicone tubes, which are common in daily life, including braided silicone tubes and transparent silicone tubes. However, as an ordinary user, apart from distinguishing the appearance of the hose, it is currently unclear what the difference is between the two. Let's take a look at the similarities and differences between these two types of silicone tubes.

Transparent silicone tube: Made from imported silicone raw materials and processed by extrusion. Generally used for transporting certain organic solvents and corrosive liquids. Usually used as food filling equipment, supporting hoses and peristaltic pump delivery hoses. Widely used in hygiene drugs, food filling, and industrial applications.

Woven silicone tube: Made from imported food grade silicone raw materials, processed by platinum vulcanization. The hose complies with US food hygiene regulations and can be temporarily used in the food and pharmaceutical industries. Widely used in industries such as food, wine, beverages, dairy products, cosmetics, toothpaste, fine chemicals, pharmaceuticals, hygiene, and biotechnology.

During the molding process of silicone tubing, an important step is high-temperature vulcanization. The hardness of the silicone tubing is determined by the hardness of the raw material, but the temperature during the processing will have a corresponding impact on the hardness of the tubing. If the temperature is too high or the high temperature time is too long, the hardness of the finished product will change. But if the temperature is too low, such as minus 20 degrees Celsius, the hardness will become relatively hard and easy to break. But it has no effect on hardness at room temperature. So when producing silicone tubes, high temperature control is required because the softness and hardness of silicone tubes will change with temperature.

The above is the difference between two types of silicone tubes, both of which use natural silicone raw materials, but have significant differences in production processes. Transparent silicone tubing is produced by extrusion method, while braided silicone tubing should be subjected to platinum vulcanization for secondary vulcanization to ensure the fusion of the tubing wall and braided wire.