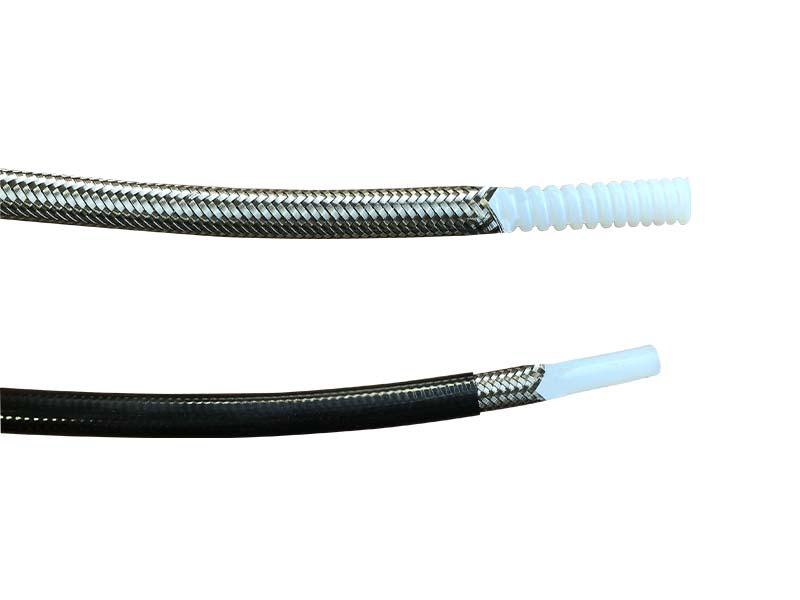

佳润科技PTFE薄壁高压管突破70MPa

时间:2022-04-28浏览次数:3383聚四氟乙烯(Poly tetra fluoroethylene 简称PTFE)俗称“塑料王”,具有优良的物理特性(可在-180~260℃温度范围、PH1~14强酸强碱工作环境下长期使用,优良的绝缘性和自润滑性),广泛应用于机械、电子、医疗、航空航天等各种特殊工况下使用环境。

2018年以来,面对中美贸易战,国外高端原材料封锁,叠加疫情影响,对于依赖高端原料进口的企业,生产和研发近乎停滞。面对前所未有的挑战,我司积极寻求国内替代方案,并积极优化产品配方和生产工艺。经过公司研发部门不懈努力,PTFE原料采用国产替代料配合我司独有研发的配方工艺(性能参数见下表),PTFE薄壁(壁厚1mm)复合管耐压测试成功突破70MPa,该产品能满足客户复杂工况下使用要求。新产品已实现量产,并陆续发送客户。

近年来面对复杂多变的国际国内环境,佳润科技始终秉持公司理念“优良的品质 准确的交期 合理的价格 贴心的服务”,不断加大研发投入,攻坚克难,为客户解忧,为行业突破技术瓶颈而努力。

|

序号 |

项目 |

JPTFE性能参数 |

|

1 |

体积密度g/L |

420±50 |

|

2 |

拉伸强度 MPa≥ |

30 |

|

3 |

断裂伸长率%≥ |

320 |

|

4 |

含水率%≤ |

0.02 |

|

5 |

标准相对密度 |

202±0.1 |

|

6 |

平均粒径μm |

400~575 |

|

7 |

[敏感词]压缩比 |

1000~1500 |

|

8 |

挤出压力MPa |

20~50(500:1) |

|

9 |

热不稳定指数≤ |

10 |

|

10 |

熔点℃ |

325±5 |

|

11 |

加工方法 |

糊状挤出 |

|

12 |

优点 |

耐压性好,耐热性好,透明性好,耐强酸强碱 |