Introduction to bestyield rubber refining center

时间:2022-04-21浏览次数:20801、 Project background of rubber refining center

1. Limited existing capacity

The existing small tipper internal mixer has small specifications, low configuration and low mixing efficiency. It takes 20 minutes or even longer to hit the first hand glue, while the falling type is used to hit the first hand glue

It usually takes only 3-5 minutes. The existing equipment capacity can no longer meet the production demand of the company.

2. Low degree of automation of existing equipment

Small materials are manually batched, which is inefficient and easy to make mistakes. There is no information linkage between open refining and internal mixing equipment, and the production process needs to be operated by employees

It leads to high labor intensity and difficult quality control. Under the general trend of the country vigorously advocating intelligent manufacturing, the company's existing equipment has been unable to keep up with the situation.

3. Improvement of production environment

Batching, feeding and refining are completely completed manually. Although dust removal and other measures are taken on site, it is still impossible to completely avoid potential health hazards to employees.

4. Enterprise strategy upgrading

Enterprise development is like sailing against the current. If you don't advance, you will fall back. The market is cruel. Standing still will only gradually marginalize or even eliminate the company. 18 companies have been established

Years, such as 18-year-old youth, is the time to overcome difficulties, break through bottlenecks, and stand on a new level.

Considering the cost and risk issues, the product factories in the industry basically adopt the form of processing or buying glue, superimposing the epidemic situation, trade war, raw material price rise, and the general environmental situation

However, we still decided to invest 20 million yuan to build our own rubber refining center.

2、 Characteristics of rubber mixing Center

1、Upper auxiliary / material conveying

I. the large powder is transported to the roof daily storage bin by positive pressure and high-pressure dense phase transportation, with high conveying efficiency and mature technology;

II. The unpacking feeding port is placed on the second floor, so there is no need to build a four story plant, which saves the construction cost;

III. separate and close the unpacking room to avoid dust damage to workers' health and quality.

2、Upper auxiliary / large powder weighing (oil scale)

I. adopt the double scale structure, weigh one hand in advance and put it in the middle bucket for standby, so as to effectively improve the production efficiency;

II. Check the scale in the middle to ensure that the material weight is accurately consistent with the formula and improve the product quality;

III. error proofing function, which can prevent abnormal power failure or abnormal weighing, and can be discharged from the rear material port in time.

3、Feeding of auxiliary / rubber and small materials

I. the rubber scale is equipped with the recheck function to ensure that the feeding weight is consistent with the formula;

II. The feeding belt is equipped with metal detection to prevent metal foreign matters from entering the equipment and affecting the quality.

4、Internal mixer

I. the core equipment adopts the domestic top internal mixer brand, and adopts the latest pes5 meshing rotor structure, with high mixing efficiency;

II. The mixing chamber, the upper and lower top bolts and the rotor are equipped with internal circulating water channels, which can accurately control the material temperature within ± 5 ℃ with the independent temperature control device of the equipment.

Rubber refining is a temperature sensitive link, and accurate temperature control will make the quality more stable;

III. hydraulic upper jacking bolt is adopted, with accurate control, large downward pressure and stability without floating;

Ⅳ. 10kv High-voltage variable-frequency drive is adopted, which has less power loss and more energy saving. The speed can be adjusted arbitrarily to adapt to various complex processes.

5、Lower auxiliary / open mill

I. double frequency conversion motors are used to drive two rollers respectively, and the speed / ratio of front and rear rollers can be adjusted arbitrarily, with strong process adaptability;

II. The front and rear rollers adopt the drilling structure, and the cooling water channel is close to the working face, so the cooling effect of the roller surface is better;

III. hydraulic distance adjustment is adopted, with high distance adjustment accuracy. It can adjust the distance with material. It is safer to quickly open the roll distance within 5S under abnormal conditions;

Ⅳ. It is equipped with an automatic turning device, which eliminates the need for manual triangle packing and reduces the labor intensity of workers.

6、Lower auxiliary / film cooling

I. the hanging rod structure is adopted, which is cooled through the cooling separator tank and then equipped with air cooling, double cooling, and the film temperature after cooling is ≤ 5 ℃ at room temperature;

II. Automatic cutting is equipped for a-glue output, and the manipulator automatically grabs and palletizes the pieces, which has high efficiency, saves labor, and reduces the labor intensity of workers;

Ⅲ. The mechanical arm is used to automatically swing the strip into the frame for the stripping of B glue, which has high efficiency, saves labor and reduces the labor intensity of workers.

7. Automatic small material weighing

I. the accuracy is ± 10g, which ensures that the counterweight of small amount of materials meets the requirements of the formula, improves the quality of rubber materials, and saves costs at the same time;

II. Programmed weighing control, the equipment automatically weighs according to the input formula to prevent human participation from causing errors;

III. high weighing efficiency, batching capacity of 180-240 bags / shift, which can meet the production needs of at least three lines at the same time;

Ⅳ. Each kind of small material is weighed independently in a closed way, equipped with independent dust removal equipment, and there is no dust on site to avoid physical injury to workers.

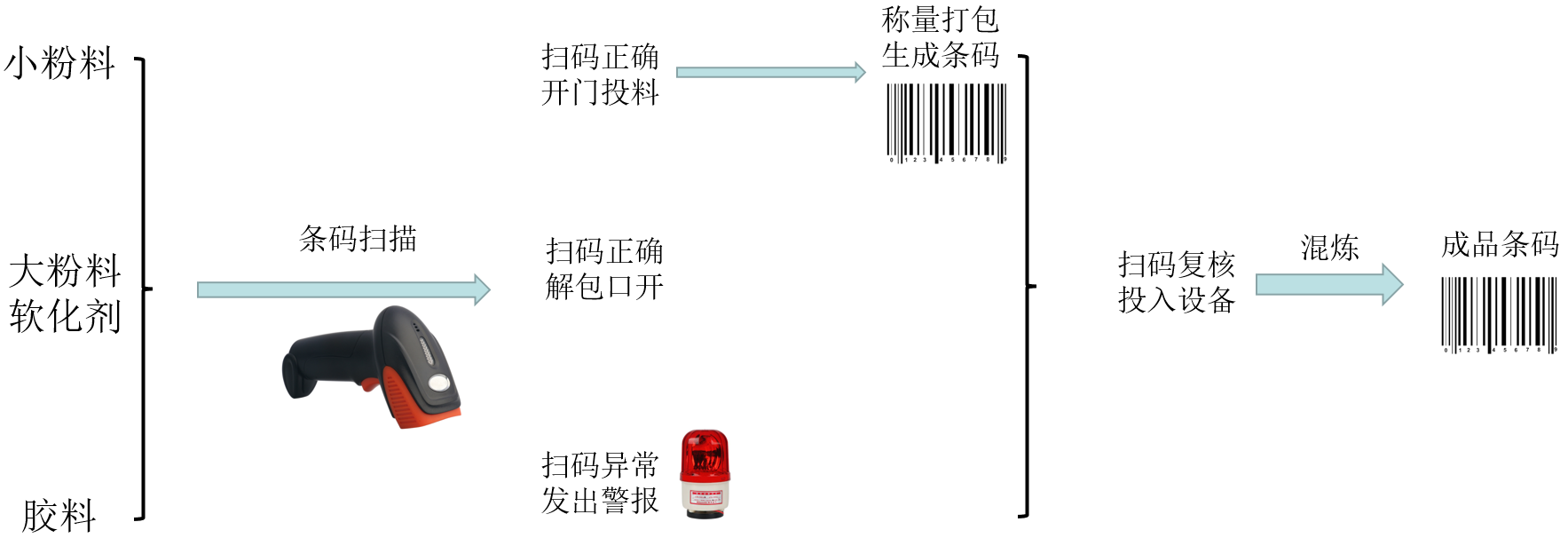

8. Informatization quality control

Mixing realizes closed-loop control from raw materials to finished products, preparing for the next step of MES system to realize the informatization and intellectualization of the whole production base

3、 Looking ahead

1. No longer troubled by insufficient capacity

Capacity accounting of rubber refining center

140L × zero point six five × 1.2kg/L × tenhand/h × 10h × three hundredDays ≈three thousand and three hundredton/year

Once the rubber mixing center is completed and put into operation, the production capacity will be released, and the production of products will no longer be limited by the rubber mixing capacity. In the past, orders that can be accepted but dare not be accepted because of capacity problems, and customers that can serve but dare not be served will be completely solved.

2. Initially achieve the goal of intelligent manufacturing

The rubber mixing center realizes the error proofing of raw material feeding bar code, automatic weighing and rechecking feeding, automatic refining and stacking, and finally automatic strip stacking, and pastes the traceable bar code containing production information. The mixing will fully realize the closed-loop quality control from raw materials to finished products. Thanks to the realization of automation, many manual intervention links are reduced, which will further improve the product quality.

3. Benefit employees

Due to the realization of automation and the reasonable layout of the production line, the production links that need to be completed manually before will be completed automatically by the equipment, which greatly reduces the labor intensity of workers.

4. Accelerate the development of enterprises

We know that the more difficult the market environment is, the more opportunities for enterprise development. When others are afraid, we move forward bravely. Once the market warms up, we will seize the opportunity in advance and develop faster than others.

All this is just for realization

Our commitment

Excellent quality and accurate delivery date

Reasonable price and considerate service

Article editor: Matthew Liu