Daily application precautions for steel wire braided rubber hoses

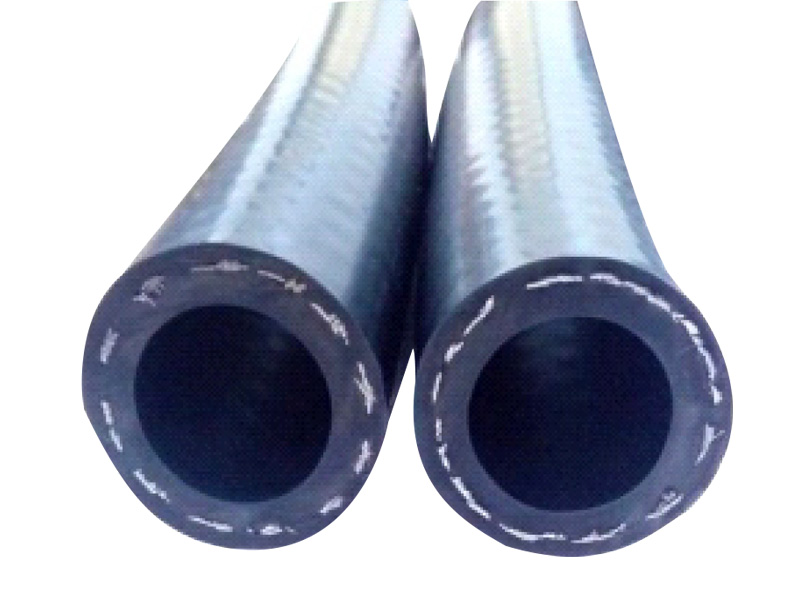

Time:2023-08-01Page views:1389High pressure rubber hoses are generally divided into steel wire braided hoses and steel wire wrapped hydraulic hoses, which are composed of inner and outer rubber layers and steel wire skeleton layers. They are usually used for hydraulic supports or engineering machinery to transport petroleum based and water-based liquids within the pressure and temperature range. Due to the complex variety, diverse structures, and different usage conditions of rubber hoses, the service life of rubber hoses depends not only on their quality, but also on whether they are used and maintained correctly.

Precautions for using steel wire braided rubber hose:

1. The high-pressure hose assembly can only be used to transport designed materials and must not be used under pressure exceeding the design working pressure (including impact pressure). In general, the temperature of the conveying medium should not exceed -40 ℃~120 ℃, otherwise it will reduce its service life. It is also not suitable for use in situations with small bending radii, and avoid bending or folding near pipe joints, otherwise it will hinder hydraulic transmission and material transportation or damage the hose assembly.

2. The rubber hose should be kept clean, and the interior should be rinsed thoroughly to prevent foreign objects from entering the lumen, obstructing fluid delivery, and damaging the equipment.

3. The length changes caused by high pressure (-4% -2%) and mechanical motion should be used correctly. If it exceeds the service life or storage period, it can continue to be used after experimental identification.

4. When using and handling high-pressure hoses, it is still necessary to be careful to avoid damaging the hoses due to negligence. During transportation, it is not allowed to drag and avoid bending or folding of the pipe body. For rubber hoses transported in a straight line, when the length exceeds the loading compartment, the extra long part should be supported by a bracket to prevent the product from being dragged and damaged on the ground.

The service life of steel wire braided rubber hose depends on quality and correct use. Although it has a multi-layer structure with steel wire wrapped inside, it is still very fragile.