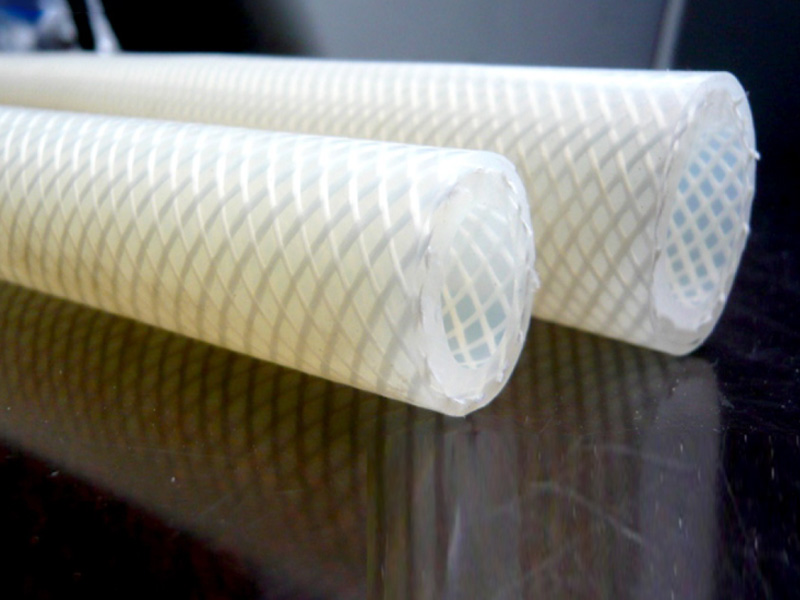

编织硅胶管挤出和编织工艺

时间:2023-03-17浏览次数:999

编织硅胶管生产过程中的一步就是挤出内管,在挤压内管时要求尽可能使壁厚在1至2毫米之间。如果内胎壁厚太薄,会导致在没有支撑的情况下,在编织纤维线时,柔软的织物很容易脱落,导致织造失败。有特殊要求者可定制内管,可制成耐高温、彩色、阻燃等,用于特殊领域,如内管为黑色,外管是透明的,内管是耐高温胶,外管是普通的,高透明胶都有,说明内管的生产工艺可以满足各行业的需求。

挤出内管之后就需要编织纤维线了,常规的编织硅胶管可以达到抗压12~38公斤以上,但是有些定制类的客户则不需要抗压他们通常是需要耐负压或者超高压,此时纤维线是无法满足客户要求,会通常采用高强度的编织物比如尼龙钓线,在更换了编织物之后使产品抗压或者抗负压能力加强,需要注意的是钢丝硅胶管是不能进行编织的。将内管通过编织机拉过由几个编织头组成的编织网。此时,编织网将包裹内管(编织头将被编程为按照固定的路线编织,所以看到的编织硅胶线是有规律的,而不是随机的),常规的编织硅胶管都需用编织机进行,所以这是个重要环节。由于硅橡胶硫化工艺是在高温下进行的,因此需要调配好机头,只要其中一个头出现问题,就会引起产品织造的混乱。

内管和编织线制作完成后就是进行挤出外管,这个环节看起来简单实际也是很麻烦的,需要注意内管外裹着纤维线在通过挤出机的时候会造成有内部空间的出现会携带者少量空气,此时硅胶外管如果挤出就会有气泡出现导致外管凹凸不平,解决方法是可以将外管壁厚适当做厚一点点,硅胶外管在挤出的时候外管的料重的时候硅胶会适当的收缩更紧将内部空气强行挤出到外界可以减轻此类问题出现,另外一个原因就是外管壁厚增加会将原本凹凸不平的外壁进行填埋处理,这样就可以解决表面凹凸不平的情况发生,挤出外管也是编织硅胶管制作流程也标志着完结。