Characteristics of Steel Wire Reinforcement Layer in Steel Wire Braided Rubber Hose

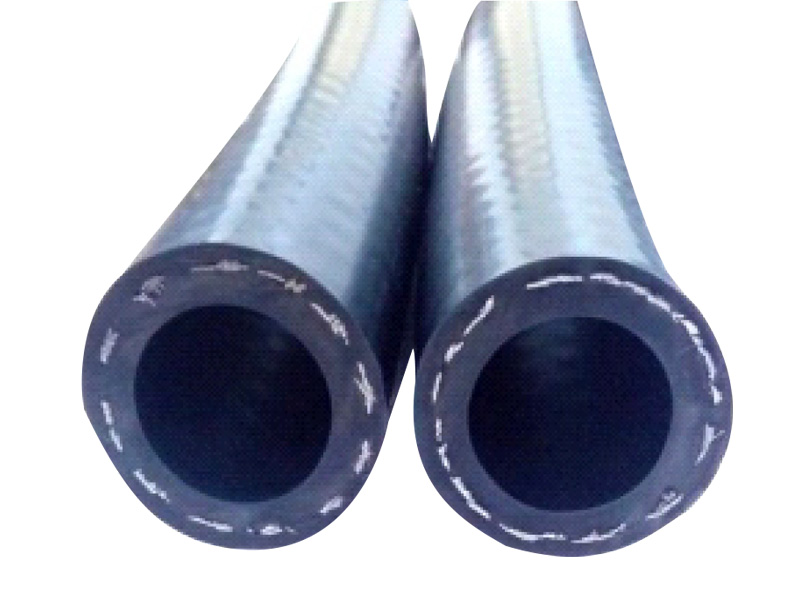

Time:2025-01-07Page views:906As an important component in modern industry, steel wire braided rubber hoses are widely used in various fluid transmission systems under high pressure, high temperature, and complex environments. Its pressure resistance, aging resistance, and wear resistance are largely attributed to its unique structural design, especially the presence of steel wire reinforcement layers. This article will explore the characteristics of the steel wire reinforcement layer in the construction of steel wire braided rubber hoses, in order to provide readers with a comprehensive and in-depth understanding.

1、 Structural characteristics of steel wire braided reinforcement layer

The steel wire weaving reinforcement layer is composed of high-strength and high toughness steel wires woven symmetrically in both directions at specific weaving angles and densities. This structure not only provides strong support, but also ensures that the rubber hose can maintain structural integrity during bending and twisting.

The number of layers of steel wire is also a key factor affecting its performance. Although increasing the number of layers can improve its pressure resistance, too many layers can lead to a complex weaving process, making it difficult to achieve an ideal balance state and potentially reducing overall performance. Therefore, in practical applications, it is necessary to choose the number of layers and weaving density of steel wire reasonably according to the specific requirements of working pressure and working environment.

2、 Performance characteristics of steel wire reinforcement layer

1. High strength and toughness: The key to the ability of steel wire braided rubber hoses to withstand high pressure without deformation or rupture is the high strength and toughness of the steel wire reinforcement layer. High strength steel wire can provide sufficient support to ensure that the hose can remain stable under extreme conditions. At the same time, good toughness makes the steel wire less likely to break when subjected to external impact, thereby extending the service life of the hose.

2. Corrosion resistance: In highly corrosive environments such as mine hydraulic supports and oil field extraction, the corrosion resistance of steel wire is particularly important. High quality steel wire material can resist chemical and electrochemical corrosion, protect the internal structure of the hose from corrosion, and ensure the safety and stability of fluid transmission.

3. Wear resistance: During fluid transmission, the steel wires inside the steel wire braided hose will be washed and worn by the fluid. High wear resistant steel wire can reduce the performance degradation caused by wear and ensure that the rubber hose can maintain good working condition after long-term use, which is of great significance for improving equipment efficiency and reducing maintenance costs.

4. Aging resistance: Although the outer rubber layer of the steel wire braided rubber hose is directly exposed to the external environment, the protection of the inner and middle rubber layers, as well as the structural stability of the steel wire reinforcement layer, make the entire rubber hose system have good aging resistance. This includes light resistance, ozone resistance, and weather aging resistance, ensuring that the hose can maintain stable performance in various harsh environments.

3、 Application and advantages of steel wire reinforcement layer

Steel wire braided rubber hoses are widely used in aircraft fuel systems, mine hydraulic supports, oil field extraction, and hydraulic systems of engineering machinery equipment due to their unique structure and excellent performance. In these fields, rubber hoses need to withstand the transmission tasks of high temperature and high pressure liquids such as kerosene, engine oil, and red oil (flammable and explosive media), while also requiring good resistance to bending and fatigue. The presence of a steel wire reinforcement layer enables the hose to meet these stringent requirements, ensuring the safety and stability of fluid transmission.

In addition, steel wire braided rubber hoses also have advantages such as long length, easy installation and maintenance. Especially in large engineering equipment, long-distance fluid transmission often requires the use of tens or even hundreds of meters of rubber hoses. With its high strength, toughness, and excellent wear resistance, it can ensure stable performance during long-term, high load operation.

4、 Design and Optimization of Steel Wire Reinforcement Layer

With the continuous development of industrial technology, the design of steel wire braided rubber hoses is also constantly being optimized. In order to improve production efficiency and reduce costs, wire winding technology has gradually replaced traditional weaving techniques. The reinforcement layer of the steel wire wrapped rubber hose is composed of even layers of steel wires alternately wound in both directions, which not only effectively utilizes the strength of the steel wires, but also improves production efficiency. However, compared to braided pipes, wrapped pipes may have certain limitations in terms of bending performance. Therefore, trade-offs need to be made during design based on specific application scenarios and requirements.

In addition, the bonding performance between the steel wire reinforcement layer and the inner and outer rubber layers is also a key issue that needs to be paid attention to during design. Good adhesion performance can ensure a tight bond between the steel wire and the adhesive layer, preventing delamination or peeling during use. To achieve this goal, it is usually necessary to add a special adhesive to the intermediate adhesive layer to improve the bonding strength between the steel wire and the adhesive layer.

The steel wire reinforcement layer in the construction of steel wire braided rubber hoses has excellent properties such as high strength, high toughness, corrosion resistance, wear resistance, and aging resistance. These performance characteristics make it play a role in aircraft fuel systems, mine hydraulic supports, oil field mining, and hydraulic systems of engineering machinery and equipment. By continuously optimizing design and production processes, the performance of steel wire braided rubber hoses will be further improved, providing more reliable support for the development of modern industry.