Performance advantages and operational characteristics of woven silicone tubing

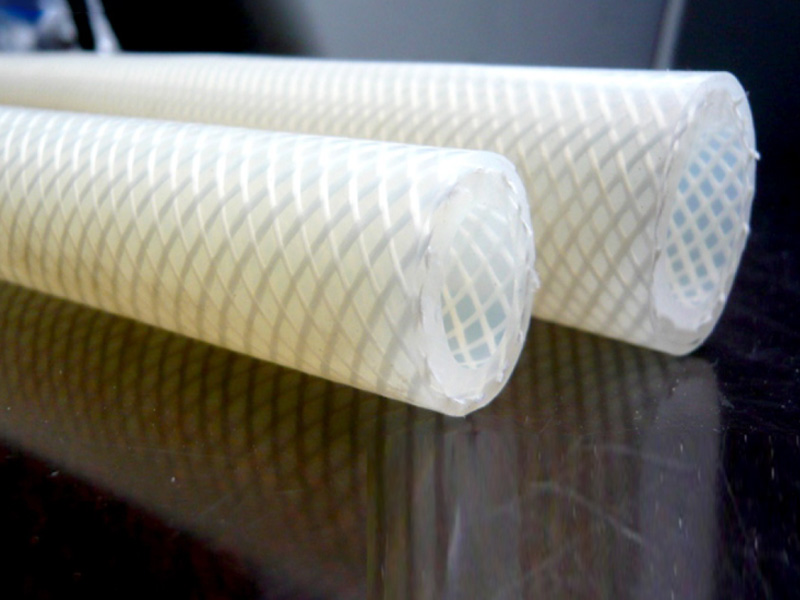

Time:2025-03-18Page views:504Woven silicone tubingAs a high-performance special silicone tubing, it plays a role in various fields such as industry, medicine, and aerospace due to its ability to withstand pressure and adapt to special environmental operations. This article will explore the material properties, production processes, application areas, and performance of woven silicone hoses in special environments, aiming to provide readers with a deeper understanding.

1、 Material characteristics

The core of woven silicone tubing lies in its unique weaving structure, which is usually composed of one or more layers of high-strength fibers, such as polyester fibers, nylon fibers, or stainless steel wires, sandwiched between the inner and outer layers of silicone material. This design not only significantly improves the compressive strength of the pipe, but also enhances its tear resistance and wear resistance. The outer silicone material has good elasticity and weather resistance, which can resist the erosion of environmental factors such as ultraviolet rays and ozone; The inner layer of silicone ensures the purity and chemical stability of the fluid, making it suitable for transporting various corrosive media.

The addition of the weaving layer enables the silicone tube to effectively disperse pressure when subjected to high pressure, avoiding the risk of single point rupture. At the same time, the weaving layer can also provide certain radial support, keeping the pipe structurally stable and not easily deformed when bent or twisted. This comprehensive performance improvement makes braided silicone tubing an ideal choice for extreme conditions such as high pressure, high temperature, and high wear.

2、 Production process

The production process of woven silicone tubing involves multiple precision steps, from the selection of raw materials to the inspection of finished products, each step is crucial. Firstly, it is necessary to use high-quality silicone raw materials and weaving materials to ensure the basic performance of the product. Subsequently, the silicone material is heated and melted through an extruder, and extruded into a tube shape. This process requires strict control of temperature, pressure, and extrusion speed to ensure the uniformity and dimensional accuracy of the tube.

The weaving process is a key link in the entire production process. The weaving machine weaves pre selected fibers or metal wires evenly between the outer or inner layers of the silicone tube according to certain rules and tension. The tightness and angle of the weaving directly affect the strength and flexibility of the tube. After vulcanization treatment, the silicone material is fully cross-linked and cured, enhancing the durability and chemical stability of the pipe.

3、 Application Fields

Woven silicone tubing, with its unique performance advantages, has shown a wide range of application prospects in multiple fields.

1. In the industrial field, woven silicone tubing is often used to transport high-pressure, high-temperature, corrosive fluids such as steam, acid and alkali liquids, oils, etc. in industries such as petroleum, chemical, and metallurgy. Its excellent chemical corrosion resistance and high temperature stability ensure the safety and efficiency of fluid transportation.

2. In the medical field, braided silicone tubing is widely used in systems such as hemodialysis and drug infusion due to its non-toxic, odorless, and biocompatible characteristics. Its good elasticity and fatigue resistance ensure stability and reliability for long-term use.

3. Aerospace: In these high-tech fields, woven silicone hoses are used in key areas such as missile fuel delivery and aircraft hydraulic systems due to their high strength, high pressure resistance, and low temperature resistance (-60 ℃ to 200 ℃). Its performance ensures stable operation under extreme conditions.

4. Other special environments: In extreme environments such as deep-sea exploration and polar exploration, braided silicone tubing has become an indispensable component in these fields due to its excellent low temperature resistance, seawater corrosion resistance, and other properties.

4、 Performance in special environments

In special environments, woven silicone tubing has demonstrated unparalleled advantages. For example, in deep-sea environments, high water pressure places high demands on the compressive performance of pipes. The woven silicone tube, with its reinforced layer, can withstand high pressure several times that of seawater, ensuring the stable operation of deep-sea exploration equipment. Meanwhile, its resistance to seawater corrosion prevents damage to the pipes caused by long-term immersion.

In polar exploration, low temperature and strong ultraviolet radiation pose severe challenges to the low temperature and weather resistance of pipes. Woven silicone tubing, with its excellent low-temperature resistance and UV resistance, can maintain softness and elasticity at extreme low temperatures of -60 ℃, while resisting UV erosion, ensuring the normal operation of polar scientific research equipment.

In addition, in the aerospace field, woven silicone tubing also needs to face the huge vibrations and impacts generated by high-speed flight. Its good elasticity and fatigue resistance make the pipe less prone to damage when subjected to severe vibrations, ensuring flight safety. At the same time, its excellent high temperature resistance enables the pipe to maintain good working condition in high temperature environments.

As a high-performance special silicone tubing, braided silicone tubing plays a role in many fields due to its compressive resistance and adaptability to special environmental operations. With the advancement of technology and the deepening of applications, the performance of woven silicone hoses will continue to be optimized and improved, and their application fields will also be further expanded.