Transportation and installation requirements for high-pressure steel wire braided rubber hoses

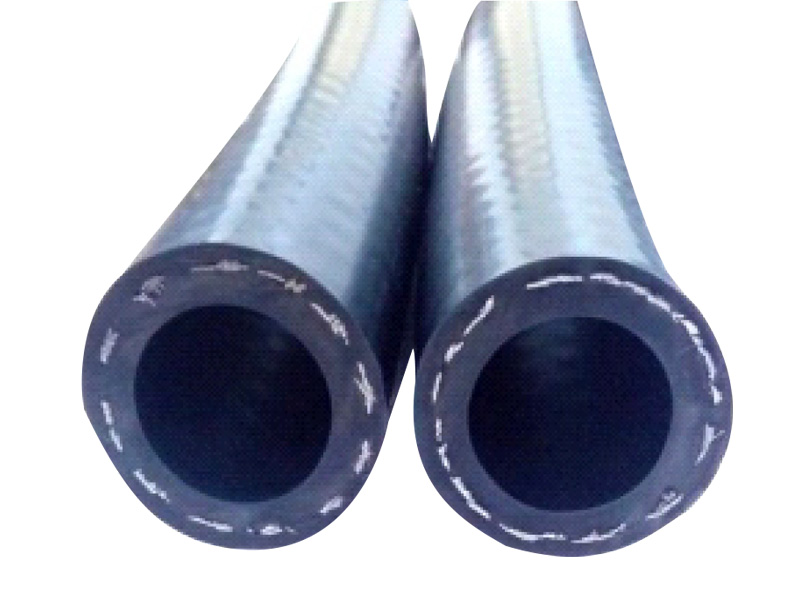

Time:2024-05-07Page views:958High pressure steel wire braided rubber hose has high pressure resistance, excellent pulse performance, excellent heat resistance, oil resistance, and aging resistance. Although it has a multi-layered structure and is wrapped in steel wire, it is still very fragile and requires special attention during use and handling.

1、 Transportation and storage requirements

1. During transportation, loading and unloading, it is not allowed to drag and drop at will.

2. Rubber hoses should be neatly classified and transported in rolls (strips). Avoid bending and folding, and do not stack other heavy objects.

3. For rubber hoses that require straight transportation, when the length exceeds the loading compartment, the extra long part should be supported by brackets to prevent the product from being dragged on the ground and damaged.

4. During the loading and unloading process, handle with care.

5. When the product needs to be temporarily parked in the open air (or workshop dock) for some reason, the site needs to be flat, and the placement should be neat and flat, with a cover plate below. Heavy objects should not be stacked on top, and it should not come into contact with heat sources.

6. It is strictly prohibited to mix with acids, alkalis, oils, organic solvents, flammable and explosive materials, and the pipe body should not come into direct contact with sharp edged objects.

2、 Precautions during installation process

1. Do not twist the hose during installation to avoid damage or loose connections when under pressure.

2. When the bending radius is too small, attention should be paid. A more reasonable approach is to use right angle joints to prevent bending and twisting.

3. When under pressure, the length of the hose will change, and no fixing device should be added at the bend. The hose should be allowed to move freely. Once fixed, it is easy to cause increased wear and tear on the buckle.

4. To prevent damage to the hose and limit flow, the bending radius should be increased as much as possible.

5. Remember not to twist the rubber hose during installation, otherwise it is easy to damage the hose or loosen the compression joint when under pressure.

6. When installing high-pressure steel wire braided rubber hoses between objects, corresponding space should be left to prevent friction between the hose and the object during operation. If prevention is not possible, some protective measures can be taken, such as using a protective sheath.

According to different applications and effects, high-pressure steel wire braided rubber hoses have different models and specifications. Another aspect is that different layers result in different usage locations, which also determines its specifications and characteristics. If the installation is not done well during the installation process, reinstalling it is time-consuming and laborious. If not installed properly, it can also affect the lifespan of the hose, and in severe cases, it may cause hidden dangers.