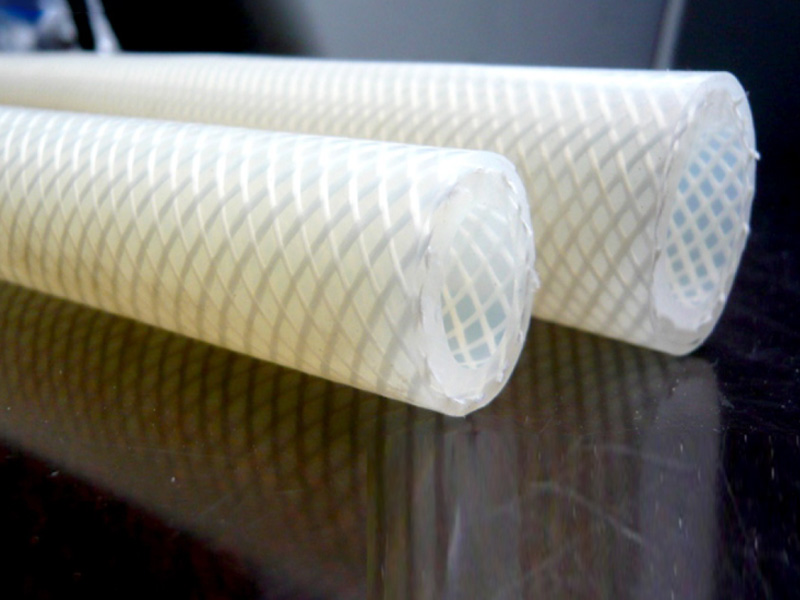

Application characteristics of woven silicone tubing

Time:2024-02-27Page views:1022Woven silicone tubing has a long aging resistance, and its lifespan varies depending on the usage environment. It can be used for more than 10 years at room temperature. Mainly used in industries such as food, hygiene, medical, machinery, hardware, automotive, electronic appliances, etc. Suitable for water, oil and other products within the range of -60 ℃~260 ℃. Very suitable for liquid and gas pipelines, it can meet various needs in different working environments.

1、 Characteristics

1. Has high voltage resistance, high tear resistance, and excellent electrical performance;

2. Non toxic, odorless, and will not turn yellow after long-term use;

3. Cold resistant and high temperature resistant, capable of continuous temperature resistance up to -60 ℃~260 ℃;

4. High softness, good elasticity, no distortion or deformation, high flame retardancy, ozone resistance, and aging resistance;

5. Capable of withstanding high pressure, with a pressure range of 2.5MPa to 4.0MPa;

2、 Application advantages

1. High transparency, high hygiene level, environmentally friendly, efficient, odorless, and capable of high-temperature and high-pressure sterilization;

2. Woven silicone tubing has excellent physiological inertia and will not cause harm to human tissues. After entering human tissues, it will not cause foreign body reactions or inflammation of surrounding tissues;

3. High tensile strength, high tear resistance, low shrinkage rate, and good resilience;

4. Strong resistance to high and low temperatures, will not deform at high temperatures, and will not produce harmful substances during decomposition. Has physiological inertia and strong anti-aging ability;

Woven silicone tubing has the characteristics of high transparency, odorlessness, excellent aging resistance, high tear resistance, good resilience, no deformation, weak acid and alkali resistance, and high and low temperature resistance. Widely used as excellent electrical insulation sealing and liquid transportation materials in industrial sectors such as electronics, petroleum, chemical, mechanical, electrical, medical, oven, food, etc.