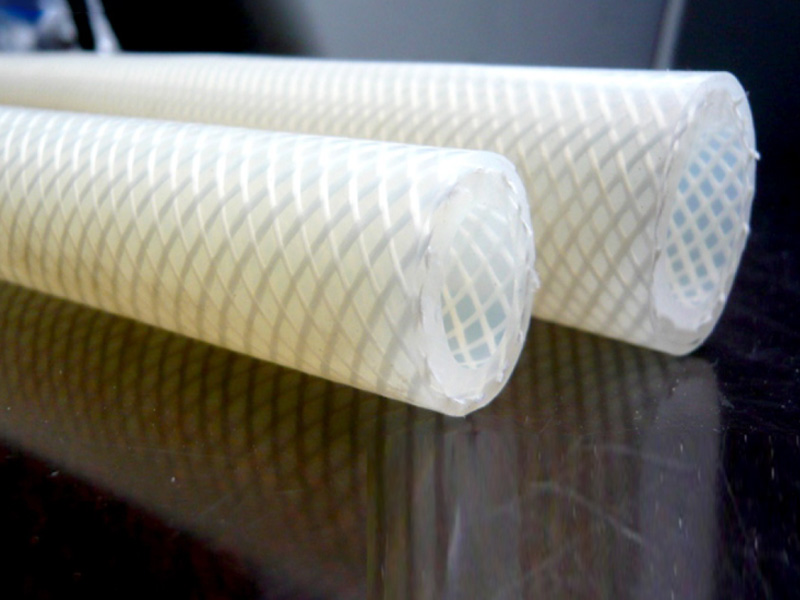

Analysis of structural reasons and control methods of braided silicone hose

时间:2022-06-07浏览次数:1687The production steps of woven silicone hose are generally natural rubber treatment - formula according to the use requirements - mixing of rubber mixer - shutdown (about 24h) - recycling - making semi-finished products - vulcanization - trimming - inspection. But refining will encounter this problem, silicone structured. Next, let's analyze the structural reasons and control methods of structural silicone hose.

Structurization refers to the phenomenon that silica reinforced silicone rubber will harden and reduce its plasticity during storage, thus gradually losing its processability. This phenomenon is called "structurization" effect. Structural silicone rubber compound needs to be remixed or heat treated to eliminate this phenomenon, but the process cost will increase.

The reasons for the structural phenomenon: one theory believes that the active silanol group on the surface of silica particles condenses with the silanol group at the end of raw rubber molecules at room temperature, resulting in the hardening and plasticity reduction of the rubber; Another theory is that because the Si OH group on the surface of silicon dioxide reacts with the Si-O bond or terminal Si OH group of raw rubber molecules to form hydrogen bonds, or even chemical bonds, the linear polysiloxane is transformed into a pseudo crosslinked or micro crosslinked semi elastic solid structure, so the rubber hardens and the plasticity is greatly reduced.

Generally speaking, there are two control methods in the production of woven silicone hose:

One is to add "structure control agent", silicone oil or silane with active groups, silicone resin, etc., which is the most commonly used method in production. For example, adding a certain amount of hydroxyl silicone oil and silazane can play a good structural control effect; The mechanism is that substances such as silicone oil with active groups react with the active hydroxyl groups on the surface of silica, thus preventing the interaction between silica and raw rubber.

Second, the surface treatment of silica, such as silane coupling agent and hexamethyldisilazane, can also prevent the structure of silica compounds. The mechanism is that the coupling agent or silazane has been coated on the surface of silica (mutual reaction or hydrogen bonding), shielding the active groups on the surface of silica, thus preventing the interaction between silica and raw rubber.

At present, hydroxyl silicone oil is commonly used, with hydroxyl content of about 8% and viscosity of about 20. The process is to leave the powder for about 8 hours, and then treat it at high temperature, so that the silicone oil can more thoroughly treat the hydroxyl groups on the surface of silicon dioxide. If the customer takes it and uses it, there is not much demand, but it is still difficult to control in actual production.

In addition, if the woven silicone hose needs to be surface treated with silica, it needs to add structure control agent and hydroxyl silicone oil, which should have a certain impact on the performance. Because structuring is a process of slowly forming hydrogen bonds, the key is how to control the formation of hydrogen bonds. White carbon black treatment is a good method, but the cost is too high. At present, the general method is to use hydroxyl silicone oil, but only additives are not enough, and process control is needed in the production process.